Picture this: you’ve spent hours baking your favorite cake or pastry, only to find that it’s stuck to the bottom of the pan like glue. Not only has your hard work gone down the drain, but now you’re left with a massive cleaning job. That’s why using the right baking pan and coating is crucial.

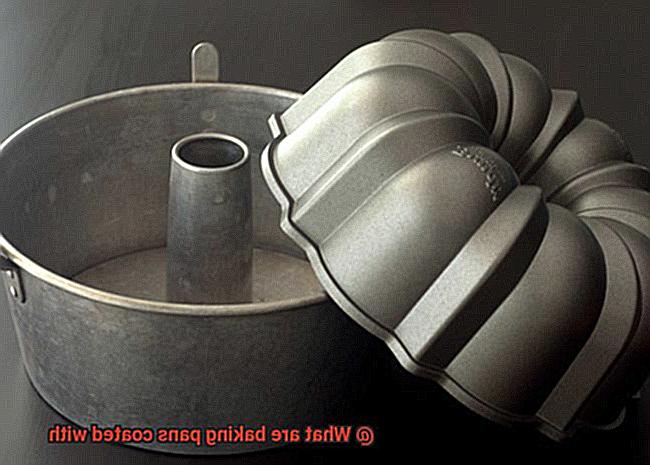

Baking pans come in a variety of coatings to ensure that your baked goods turn out perfectly and don’t stick to the pan. But have you ever wondered what these coatings are made of and how they work? Fear not, because we’re about to take a deep dive into the world of baking pan coatings.

We’ll explore everything from nonstick coatings to ceramic and silicone coatings, examining their durability, heat conductivity, and overall performance. Whether you’re a seasoned baker or just enjoy whipping up treats for fun, understanding the coatings on your pans is essential.

So buckle up and get ready to learn about the science behind baking pan coatings – because when it comes to making perfect baked goods, every detail counts.

Contents

Types of Non-Stick Coatings Used for Baking Pans

Baking is a wonderful hobby and a great way to indulge in your love for all things sweet. But let’s face it, the aftermath of baking can be an exhausting task. Thankfully, non-stick coatings on baking pans have made our lives easier. However, not all non-stick coatings are created equal. Here are the different types of non-stick coatings used for baking pans:

PTFE (Polytetrafluoroethylene) Coating

This is the most commonly used non-stick coating for baking pans. It is also known as Teflon coating and is made up of a synthetic polymer that is resistant to high temperatures. PTFE coatings are easy to clean and provide a smooth surface for baking. However, overheating or using sharp utensils can lead to damage and release harmful chemicals into your food.

Ceramic Coating

Ceramic coatings are made up of natural materials such as clay and sand. They are environmentally friendly, do not contain any harmful chemicals, and provide excellent non-stick properties. Additionally, ceramic-coated baking pans are durable, scratch-resistant, and can withstand high temperatures.

Silicone Coating

Silicone coatings are non-toxic and provide excellent non-stick properties. They are flexible and can withstand high temperatures, making them suitable for baking. Silicone coatings are also easy to clean and maintain.

Enameled Coating

These coatings provide excellent non-stick properties and are made up of a layer of porcelain or ceramic that is applied to a metal base. They are scratch-resistant, durable, and can withstand high temperatures.

Hybrid Coatings

These coatings combine elements from different types of non-stick coatings to offer the benefits of both materials. For example, some baking pans may feature a ceramic base with a PTFE top layer.

It is crucial to note that while non-stick coatings make it easier to bake and clean, they should be used with caution. Overheating the pan or using sharp utensils can damage the coating and release harmful chemicals into your food. Always follow the manufacturer’s instructions carefully and use appropriate utensils when cooking with non-stick coated baking pans.

In summary, there are different types of non-stick coatings used for baking pans. Whether you prefer PTFE, silicone, ceramic, enameled coating, or a combination of materials, there is a non-stick coating that will meet your needs and make your baking experience enjoyable.

Advantages of Using Non-Stick Coatings on Baking Pans

Enter non-stick coatings on baking pans, a game-changer in the world of baking. As an expert on the benefits of using non-stick coatings on baking pans, let me share with you why they are a must-have in any kitchen.

First and foremost, non-stick coatings make clean-up a breeze. Food is less likely to stick to the surface of the pan, making it effortless to remove any leftover residue or crumbs. No more dreading washing your baking pans after use as non-stick coatings make it possible to reuse the pan without worrying about any lingering flavors or smells from previous recipes.

But that’s not all. Non-stick coatings also prevent over-browning or burning of baked goods. Food sticking to the surface of a pan can create hot spots that cause uneven cooking. However, a non-stick coating helps distribute heat more evenly, resulting in perfectly cooked and evenly browned baked goods.

Plus, using non-stick coated baking pans can help reduce the amount of oil or butter needed in recipes. With food being less likely to stick to the pan, there is a reduced need for additional fats to prevent sticking. This not only helps those looking to reduce their fat intake but also allows for healthier versions of favorite recipes.

The Process of Applying Non-Stick Coatings to Baking Pans

Baking is a beloved pastime for many, but it can quickly become frustrating when your baked goods stick to the pan. This is where non-stick coatings come in, making baking a breeze. But how are these coatings applied to baking pans? Let’s take a closer look at the process.

The first step in applying non-stick coatings is to clean and prepare the baking pan. Any oils or contaminants must be removed from the surface of the pan to ensure that the coating adheres correctly. Once the surface is pristine, a primer is applied to promote adhesion between the coating and the metal surface. The primer is usually a liquid that is sprayed or brushed onto the pan and allowed to dry.

With the primer dried, it’s time to apply the non-stick coating. There are various types of coatings available, such as ceramic, silicone, and Teflon. Each type of coating has its unique properties and benefits, with manufacturers choosing which one to use based on their preferences and desired end-product qualities.

After applying the non-stick coating, it’s time for curing. The baking pan is heated in an oven or furnace to cure the coating. This process helps create a durable and long-lasting non-stick surface on the pan that can withstand high temperatures and frequent use.

Manufacturers take great care in their production processes to ensure that their non-stick coatings are of high quality. By following specific steps and using premium materials, they can produce baking pans that are easy to use and maintain. With non-stick coatings, you can enjoy your favorite recipes without worrying about food sticking to your pans or ruining your final products.

Other Materials Used to Enhance Performance of Baking Pans

As avid bakers, we all know the pain of having our baked goods stuck to the pan, ruining our hard work. But fret not, there are materials out there that can make our baking experience smoother and more enjoyable. As an expert on this topic, let’s delve into some of the different materials used to enhance the performance of baking pans.

First on our list is silicone. Silicone baking pans have skyrocketed in popularity due to their flexibility and non-stick properties. Made from food-grade silicone, these pans are not only non-toxic but durable and capable of withstanding high temperatures. The best part? They make cleaning up a breeze and can be used in a variety of settings like the oven, microwave, freezer, and dishwasher.

Next up, we have ceramic baking pans. These pans are made from glazed ceramic which provides a non-stick surface and even heat distribution. Not only are they functional, but they’re also aesthetically pleasing as they come in an array of colors and designs to match your kitchen décor.

Last but not least, we have non-stick coatings which are often applied to metal baking pans. These coatings are typically made from PTFE, also known as Teflon, which prevents food from sticking to the surface. While these coatings make clean-up easy, there has been some concern about their safety when heated to high temperatures. It’s crucial to use non-stick baking pans with caution and avoid overheating them.

Common Types of Anodizing for Aluminum Baking Pans

When it comes to baking pans, aluminum is a top choice due to its durability and excellent heat conductivity. However, aluminum can react with acidic or alkaline ingredients in food, causing discoloration and tarnishing. This is where anodizing comes in. Anodizing is an electrochemical process that creates a protective oxide layer on the surface of the aluminum baking pan. There are several types of anodizing used for baking pans, each with distinct properties and benefits.

Type II anodizing, also known as sulfuric acid anodizing, is a popular type of anodizing that produces a hard, durable layer of aluminum oxide on the surface of the baking pan. This layer is resistant to scratches and corrosion and also allows for coloring options, making it possible to add a decorative touch to the baking pan. Type II anodized aluminum baking pans are ideal for home use and can withstand frequent use and cleaning.

Hardcoat anodizing, on the other hand, uses a thicker layer of aluminum oxide than Type II anodizing, resulting in a more durable and scratch-resistant surface that can withstand commercial settings or high-volume baking needs. Hardcoat anodized aluminum baking pans are often used by professional bakers or those who frequently bake large quantities of goods.

Non-stick anodizing is another type of anodizing that adds a coating of PTFE or ceramic to the surface of the anodized pan. This creates a non-stick surface that makes it easy to release baked goods without sticking to the pan. Non-stick anodized aluminum baking pans are perfect for delicate pastries or cakes that require gentle handling.

Two-step anodizing is another type of anodizing used for decorative purposes. In this process, the aluminum is first immersed in a sulfuric acid bath to create a base layer of oxide and then immersed in another chemical solution to create a colored finish on the surface of the baking pan. Two-step anodized aluminum baking pans are ideal for those who want to add a pop of color to their kitchen.

Coating Stainless Steel Baking Pans with Chromium or Nickel

Stainless steel baking pans are a popular choice due to their durability and resistance to corrosion. However, without a non-stick surface, removing your baked goods from the pan can be a challenge. Fortunately, coatings like chromium and nickel can solve this problem and offer additional benefits.

Let’s start with chromium. This metal is highly resistant to corrosion and can withstand high temperatures, making it an ideal coating for baking pans. When applied to stainless steel pans, it creates a hard, non-porous surface that resists scratching and prevents food from sticking. This means you can easily remove your baked goods without leaving them behind in the pan. Plus, the chromium coating makes cleaning a breeze and helps prevent rust and corrosion. Chromium-coated pans are perfect for baking everything from cookies to roasted vegetables.

Another coating option is nickel. Like chromium, nickel is also highly resistant to corrosion and can withstand high temperatures. When applied to stainless steel pans, it creates a smooth, non-porous surface that resists scratching and prevents food from sticking. This means your cakes and muffins will come out of the pan with ease, and clean up will be a breeze. Plus, the nickel coating helps prevent rust and corrosion over time. Nickel-coated pans are perfect for baking delicate pastries like tarts and quiches.

While both coatings provide a non-stick surface and prevent rust and corrosion, they do have some potential drawbacks. Some people may be allergic or sensitive to chromium or nickel, so it’s important to consider this when using coated baking pans. Additionally, if the coating becomes damaged or scratched, it can expose the underlying stainless steel, which may lead to rust or corrosion over time. To prevent this from happening, it’s important to use care when cleaning and storing coated baking pans.

Factors to Consider When Choosing a Coating for Your Baking Pan

The solution to these problems lies in selecting the right coating for your baking pan.

As an expert in this field, I’ve done extensive research on the factors that should be considered when choosing a coating for your baking pan. Let’s dive in and explore these essential considerations that will ensure you make the best choice.

Firstly, it’s crucial to consider the material of the coating. Silicone coatings are a popular choice for their flexibility and durability. Ceramic coatings are known for their non-toxic properties and even heat distribution. Non-stick coatings like PTFE or PFOA offer excellent food release, but overheating can cause the release of harmful chemicals. Each material has its benefits and drawbacks, so it’s important to choose one that aligns with your requirements.

Thickness is another factor to consider when selecting a coating for your baking pan. A thicker coating may provide better heat distribution and protection against scratches, but it can also add weight to the pan. On the other hand, a thinner coating may be easier to handle but may not offer as much protection over time.

Lastly, consider the cleaning and maintenance requirements of different coatings. Some coatings may require special cleaning methods or cannot be washed in a dishwasher, while others may be more forgiving. It’s important to choose a coating that aligns with your cleaning habits and preferences to ensure easy maintenance over time.

Maintenance Tips for Non-Stick Coated Baking Pans

Baking is a fun and rewarding activity, but cleaning up can be a hassle. That’s why non-stick coated baking pans are so popular among bakers. They make it easy to remove baked goods without leaving any residue behind. To ensure that your non-stick coated baking pans last longer and continue to provide effortless baking and easy clean-up, follow these maintenance tips:

Use the Right Utensils

Metal utensils can scratch and damage the surface of non-stick coated baking pans, so it’s important to use silicone, plastic, or wooden utensils instead. Not only will this prevent damage to the coating, but it will also help extend the life of your pan.

Clean Gently

Abrasive cleaners, such as scouring pads or harsh chemicals, can damage non-stick coatings and reduce their effectiveness over time. Instead, use mild dish soap and warm water to clean your pan after each use. If there are stubborn stains or residue, soak the pan in warm soapy water for a few minutes before gently scrubbing with a soft sponge or cloth.

Avoid High Heat

While non-stick coatings are designed to withstand high temperatures, exposing them to excessive heat can cause the coating to break down over time. Avoid using non-stick coated baking pans under the broiler or on the stovetop, and never preheat an empty non-stick coated baking pan.

Store With Care

Stacking non-stick coated baking pans on top of each other can cause scratches or other damage to the coating. Instead, place a layer of paper towel or cloth between each pan when storing them. This will help protect the coating and keep your pans in good condition.

Check for Damage

Regularly inspect your non-stick coated baking pans for any signs of wear or damage. If you notice any scratches or chips in the coating, it’s time to replace the pan. Damaged coating can release toxic fumes when heated and can also affect the taste and appearance of your baked goods.

Conclusion

To bake like a pro, selecting the right coating for your baking pan is key. The days of scrubbing stubborn residue off pans are over thanks to non-stick coatings. These miraculous coatings make baking a breeze by preventing over-browning and sticking, while also making clean-up a snap. With various types of non-stick coatings available such as PTFE, ceramic, silicone, enameled coating, and hybrid coatings, each with its unique properties and benefits.

When choosing a coating for your baking pan, it’s crucial to consider factors like the material of the coating, thickness, and cleaning requirements. Additionally, it’s important to use appropriate utensils when cooking with non-stick coated baking pans and avoid overheating them.

Maintaining your non-stick coated baking pans is just as important as choosing the right one. To extend their life span, use gentle cleaning methods with mild dish soap and warm water. Avoid high heat and store them carefully by placing a layer of paper towel or cloth between each pan when storing.

In summary, understanding the coatings on your baking pans is essential for every baker – whether you’re a seasoned pro or just enjoy whipping up treats for fun. By following these tips and selecting the right coating for your baking pan needs, you can make perfect baked goods every time without any hassle or frustration.