Are you tired of ruining your meals with undercooked or overcooked food? Do you rely on a temperature probe to ensure that your food is cooked to perfection and safe to eat? If so, you might be wondering – do temperature probes go bad?

As an expert on the topic, I’m here to answer this burning question. Temperature probes are a crucial tool for cooking meat, poultry, fish, and baked goods. They ensure that your food is cooked thoroughly and at the right temperature. But what happens when your trusty temperature probe starts giving inaccurate readings?

In this blog post, we’ll explore everything you need to know about temperature probes. We’ll dive into how they work, what can cause them to go bad, and signs you should look out for indicating it’s time for a replacement. We’ll also provide some tips on how to maintain your temperature probe so that it lasts as long as possible.

So get ready to take notes. By the end of this post, you’ll be an expert on whether or not your temperature probe needs replacing. Say goodbye to overcooked or undercooked food and hello to perfectly cooked meals every time.

Contents

What is a Temperature Probe?

Look no further than the trusty temperature probe. This small handheld device is widely used to measure the temperature of a substance or object accurately.

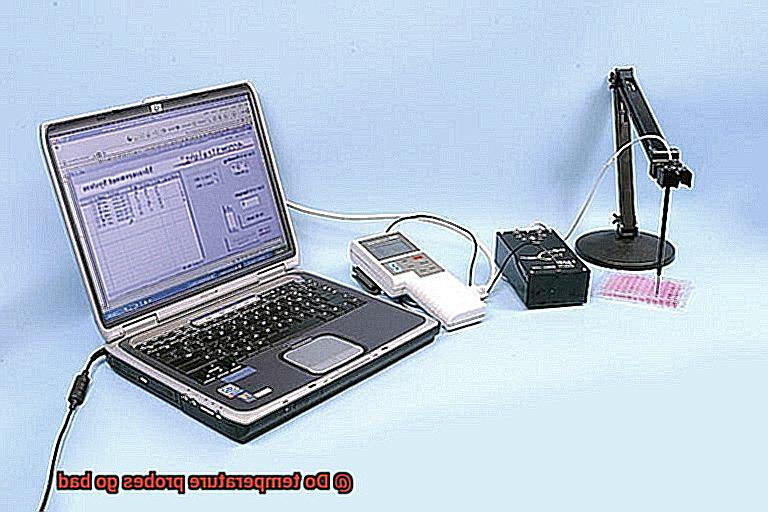

A temperature probe consists of a metal probe or sensor that connects to a display unit. By inserting the probe into the substance being measured, the unit can display the temperature reading in degrees Fahrenheit or Celsius.

There are various types of temperature probes available on the market, including thermocouples, resistance temperature detectors (RTDs), and thermistors. Each type has its own unique features and benefits, such as durability, sensitivity, and response time.

Apart from cooking, temperature probes have applications in laboratory settings, measuring chemical reactions and other substances. They’re essential tools for anyone who needs to measure temperature accurately.

However, like any tool, temperature probes can go bad over time. Some factors that can contribute to their failure include wear and tear on the wire and sensor, poor calibration, or battery failure. To avoid these issues, invest in a high-quality probe and care for it properly. Regular calibration and battery checks can also help prevent accuracy issues.

Factors that Affect the Lifespan of a Temperature Probe

You know how frustrating it can be when your trusty tool goes bad. But fear not. As an expert on the subject, I’m here to share with you the factors that affect the lifespan of a temperature probe.

Firstly, let’s talk about construction. The materials used in manufacturing a temperature probe can significantly impact its durability and corrosion resistance. Stainless steel probes are an excellent choice due to their superior durability and resistance to corrosion compared to plastic or other materials. Furthermore, thicker probes are less likely to bend or break during use, resulting in a more extended lifespan.

Next up – usage. It’s essential to keep in mind that how often and for how long you use your temperature probe can also affect its lifespan. Frequent use or prolonged periods of use can cause more wear and tear on your probe than if you used it less frequently or for shorter durations. Additionally, if your probe is exposed to high temperatures for extended periods, it may become damaged or lose accuracy over time.

Lastly, proper maintenance is crucial to extending the lifespan of your temperature probe. Regular cleaning after each use is necessary to prevent buildup on the probe’s surface, which can impact its accuracy and even lead to contamination. Warm soapy water is an excellent cleaning solution followed by thorough drying before storage. Some probes may require periodic calibration to ensure accurate readings.

Reasons Why Temperature Probes Can Go Bad

Temperature probes are a critical tool for anyone who takes their grilling or cooking seriously. However, these probes can go bad over time, leading to inaccurate readings and potentially ruining your food. Here are some of the reasons why temperature probes can go bad:

Wear and Tear

Just like any tool, temperature probes can wear out over time, especially if exposed to high temperatures for extended periods. This can cause the wires inside the probe to become damaged or frayed, leading to inaccurate readings.

Moisture

If moisture gets inside the probe, it can cause corrosion or damage to the wiring. Additionally, it can cause the probe to malfunction and provide inaccurate readings.

Improper Storage

Temperature probes should be stored properly to prevent them from becoming tangled or bent. If they’re not stored correctly, it can damage the wires inside and affect their accuracy.

Using the Wrong Type of Probe

Not all temperature probes are created equal. Using a meat probe to measure the temperature of a liquid can lead to incorrect readings and damage to the probe.

Physical Damage

Temperature probes are fragile and can easily get damaged if not handled with care. Dropping or crushing a probe can damage the sensor inside, rendering it useless.

Age

Over time, the internal components of a temperature probe can wear out or deteriorate, making it less accurate or entirely useless.

Wear and Tear

Temperature probes are a trusty tool in the arsenal of any griller or cook, but wear and tear can be a common issue that causes problems. These probes are often exposed to high heat, moisture, and other harsh conditions, which can cause damage over time. Understanding the factors that contribute to wear and tear can help you prevent issues with your temperature probes and keep your meals perfectly cooked.

One of the most common culprits behind wear and tear on temperature probes is exposure to high temperatures. When a probe is exposed to extreme heat for prolonged periods, its wires and insulation can become damaged, leading to inaccurate readings or complete failure. It’s important to keep your probes away from direct flames or extreme heat for extended periods to avoid deterioration.

Moisture is another factor that can contribute to wear and tear on temperature probes. If moisture seeps into the probe’s wiring or connectors, it can cause corrosion or short circuits that affect accuracy. Grilling in wet conditions should be avoided at all costs, and you should keep your probes dry when not in use.

Physical damage is also a major cause of wear and tear on temperature probes. Even minor drops or impacts can crack insulation or break wires, leading to incorrect readings or complete failure. Handling your probes with care and being gentle with them can go a long way in preventing physical damage.

Finally, age and usage are also factors that contribute to wear and tear on temperature probes. Over time, components may wear out or fail, which can affect the accuracy of the probe. The more frequently you use your probe, the greater the likelihood that these types of issues will arise. Regularly inspecting your equipment for signs of wear and tear and replacing any damaged components as needed is crucial.

Poor Calibration

Fear not, poor calibration is a common issue that can easily be fixed with a few simple steps.

Calibration is the process of checking and adjusting the accuracy of your temperature probe. If your probe is not calibrated correctly, it can give inaccurate readings, which can lead to overcooked or undercooked food. One of the most common reasons for this issue is poor calibration.

To avoid this problem, it’s important to check and recalibrate your temperature probe regularly. Temperature probes are calibrated using either boiling water or ice water, depending on their range. High-temperature probes use boiling water, while low-temperature probes use ice water.

To calibrate your probe, you’ll need a thermometer that is accurate to ±1°F (±0.5°C) and a container filled with either boiling water or ice water. Insert your temperature probe into the water and wait until the reading stabilizes. If the reading is not accurate, it’s time to calibrate.

Adjust the calibration screw until your temperature probe reads accurately in both ice water and boiling water. Remember, temperature probes can lose calibration over time due to regular use, exposure to extreme temperatures, or being mishandled.

Battery Failure

Whether you’re a professional chef or a home cook, a ruined meal is never a pleasant experience.

There are several factors that contribute to battery failure in temperature probes. Exposure to extreme temperatures is one of the main culprits. It’s crucial to store your probe in a safe place when not in use and avoid leaving it in environments that are too hot or too cold. Leaving your probe on for extended periods of time can also drain the battery faster, so always be sure to turn it off when not in use.

Using high-quality batteries and replacing them regularly is essential in preventing battery failure. Don’t skimp on cheap batteries – invest in good ones to ensure accurate readings every time. Some probes have automatic shut-off features that help conserve battery life as well.

If you suspect that your temperature probe is experiencing battery failure, there are several signs to look out for. Inconsistent or inaccurate readings are the most obvious symptom. Slow response times and a display that doesn’t light up properly are also telltale signs of battery failure.

To ensure accurate temperature readings, it’s important to address battery failure promptly. Replace the batteries or consider investing in a new probe altogether. Don’t ignore the issue as it can ruin your food and negatively impact your cooking experience.

Investing in High-Quality Probes

Don’t let cheap probes bring down your grilling game. Investing in high-quality probes is the key to accurate temperature readings and reliable performance over time.

When choosing high-quality probes, the material used in construction is crucial. Stainless steel is an excellent option due to its durability, resistance to corrosion, and easy-to-clean properties. The probe’s tip should also be made from heat-resistant materials like ceramic or silicone to ensure accurate readings at high temperatures.

Probe length is another important factor to consider. Longer probes provide easier placement and positioning within your grill or smoker, allowing you to monitor your meat’s temperature without opening the lid. Probes with multiple wires are also beneficial as they can measure multiple points simultaneously, providing more accurate readings.

Although high-quality probes may come with a higher price tag initially, they will save you money in the long run by providing accurate readings and reliable performance over time. Cheaper options often degrade over time, leading to inaccurate readings and even failure.

Proper Care and Maintenance for Probes

In this article, we’ll explore the importance of taking good care of your temperature probes and offer some tips to help you keep them in top condition.

Cleaning Your Probes

The first step in proper care is to clean your temperature probe after each use. This can be done by wiping it down with a damp cloth or using a mild soap and water solution. Ensuring that the probe is completely dry before storing it away is crucial as any moisture left on the probe could cause damage over time.

Calibrating Your Probes

Regular calibration is another important aspect of proper care. This ensures that your temperature probes are providing accurate readings. Calibration can be done using a calibration tool or by comparing the probe’s reading to a known accurate temperature source. Make sure to calibrate your probes regularly to avoid inaccurate readings.

Storing Your Probes

When storing temperature probes, keep them in a cool, dry place. Avoid storing them in direct sunlight or areas with high humidity as this can damage the probe. Storing them in their original packaging if possible is a good idea.

Inspecting Your Probes

Regular inspection of your temperature probes is crucial for detecting any signs of damage, such as cracks or frayed wires. If you find any damage, replace the probe immediately to avoid potential safety hazards.

Investment in High-Quality Probes

Investing in high-quality probes made of durable stainless steel with heat-resistant tips and longer lengths is essential for reliable performance over time. By spending a little extra on quality probes, you can avoid replacements and ensure the accuracy of your cooking temperatures.

mTH1FDW2NeI” >

Conclusion

In the world of cooking and grilling, temperature probes are like the trusty sidekick to your culinary adventures. They help you achieve that perfect medium-rare steak or juicy roast chicken. But just like any superhero, even they can have their weaknesses.

Over time, temperature probes can go bad due to a variety of factors such as wear and tear, poor calibration, battery failure, and improper storage. It’s important to invest in high-quality probes made from durable materials such as stainless steel with heat-resistant tips and longer lengths to extend their lifespan.

Proper care and maintenance are also crucial in keeping your temperature probes in top condition. After each use, make sure to give them a good cleaning and perform regular calibration checks. Store them properly in cool dry places away from direct sunlight or high humidity areas to avoid damage.

Don’t let a faulty temperature probe ruin your meals. By understanding the factors that affect their lifespan and taking proper care of them, you can ensure accurate readings every time you cook or grill.