Are you tired of struggling to chop vegetables or carve meat with a dull knife? A sharp knife is essential for any home cook or professional chef, and a honing steel can help maintain that sharpness. But not all honing steels are created equal. With so many options on the market, it can be overwhelming to choose the right one.

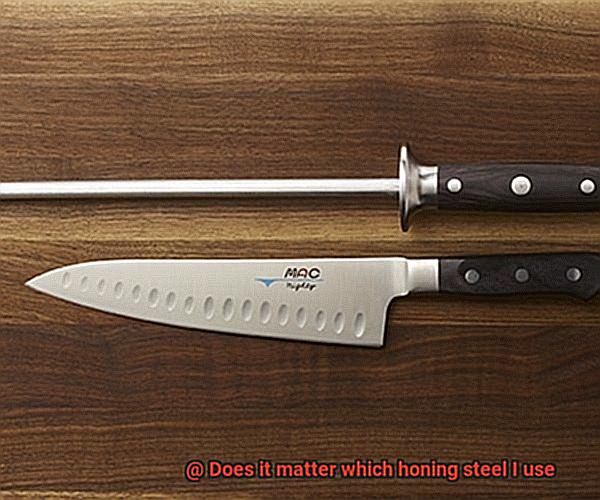

So, does it matter which honing steel you use? Absolutely. The type of steel used, the length and thickness of the rod, and the angle of the honing steel can all impact how well it sharpens your knives. In this article, we’ll explore why using the right honing steel is crucial for maintaining your knives’ longevity and sharpness. We’ll also take a look at some top honing steel options and what sets them apart.

Whether you’re an experienced chef or just starting out in the kitchen, investing in a quality honing steel can elevate your cooking game. Don’t settle for mediocre knife skills – let’s dive into finding the perfect honing steel for you.

Contents

What is Honing Steel?

If you’re a home cook or a professional chef, you know that having sharp knives is vital for preparing meals efficiently and safely. That’s where honing steel comes in. Honing steel is a cylindrical tool used to sharpen knives and maintain their edges. It is often confused with sharpening stones, which grind away metal from the blade to create a new edge.

Honing steel does not remove metal from the blade but instead straightens and aligns the existing edge. The tool is made of either ceramic or steel and measures about 10-12 inches in length with a handle on one end. The handle can be made of various materials such as plastic, wood, or rubber.

To use honing steel, hold it vertically with the tip resting on a stable surface like a cutting board or countertop. Draw the blade down the length of the steel at an angle of about 20 degrees, starting at the heel of the blade and ending at the tip. Repeat this process on both sides of the blade several times until the edge is straightened and aligned.

There are two main types of honing steel: ceramic and diamond. Ceramic honing steels are made from a hard ceramic material, while diamond honing steels have a diamond coating that makes them more abrasive. Choose the type of honing steel that corresponds to your knife’s hardness. Japanese knives with harder blades benefit from less abrasive ceramic honing steels, while German knives with softer blades require more abrasive diamond honing steels.

The length of your honing steel also matters. It should be at least as long as your longest knife to maintain its sharpness effectively.

It’s important to note that honing steel cannot replace sharpening stones or other sharpening tools. While it can help maintain an edge between sharpenings, it cannot restore a dull or damaged edge. Therefore, use honing steel as part of a regular knife maintenance routine rather than relying on it as the sole means of keeping your knives sharp.

Types of Honing Steel

Honing steel is a vital tool for keeping your knives sharp and in top condition. However, with so many different types of honing steel on the market, it can be challenging to know which one to choose. Let’s take a closer look at traditional, diamond-coated, and ceramic honing steel to help you determine the best type for your needs.

Traditional honing steel is the most basic type of honing steel. It’s typically made from a solid piece of steel with a ridged surface that helps to straighten and maintain the edge of softer blades, such as those found on kitchen knives. While traditional honing steel may not be as effective on harder blades, it’s an excellent option for maintaining the edge between sharpenings.

Diamond-coated honing steel is a newer type of honing steel that has become increasingly popular in recent years. This type of honing steel is coated with diamonds, making it more abrasive and effective at sharpening even the dullest blades. Diamond-coated honing steel is particularly useful for harder blades, like those found on hunting knives, that require more aggressive sharpening.

Ceramic honing steel falls somewhere in between traditional and diamond-coated honing steel. It’s made from a ceramic material that is harder than traditional honing steel but not as hard as diamond-coated honing steel. Ceramic honing rods are slightly more abrasive than traditional honing rods, making them ideal for maintaining the sharpness of your knife’s edge while removing only a small amount of metal with each use.

When selecting a honing steel, it’s essential to consider the type of knife you have and how dull it is. For softer blades, traditional honing steel may be the best option for you. For harder blades, diamond-coated honing steel may be more effective. And if you’re looking for something in between, ceramic honing steel may be the way to go.

Factors to Consider When Choosing a Honing Steel

With numerous options available, it can be overwhelming to make a choice. Fortunately, I have compiled a comprehensive list of factors to consider when choosing a honing steel.

Firstly, the material of the honing steel plays a vital role. Ceramic, diamond, and steel are the common materials used in honing steels, and each has its own unique benefits and drawbacks. Ceramic honing steels are gentle on blades but are not as durable as diamond or steel honing steels. Steel honing steels are suitable for softer blades, while diamond-coated steel is ideal for tougher blades.

Secondly, the length and width of the honing steel matter. The length of the honing steel should match the length of your knife. If the honing steel is too short, it won’t be able to hone the entire blade correctly. Likewise, if the honing steel is too wide, it might not fit comfortably in your hand.

Thirdly, the shape of the honing steel is an essential factor to consider. Honing steels come in different shapes like oval, round, and flat. Oval-shaped honing steels are excellent for sharpening curved blades while flat-shaped honing steels work best for straight blades.

Fourthly, the grit of the honing steel matters. Grit refers to how rough or smooth the surface of the honing steel is. A higher grit means a smoother surface, while a lower grit means a rougher surface. If you have a very dull knife, you may want to use a lower grit honing steel to remove any nicks or chips in the blade. In contrast, if you have a relatively sharp knife, a higher grit honing steel will be sufficient for maintaining its edge.

Lastly, you should consider the brand and price of the honing steel. While there are many affordable options on the market, investing in a high-quality honing steel can make all the difference in maintaining your knives’ sharpness over time. Some reputable brands include Wusthof, Shun, and Global.

Ceramic Honing Steels

These honing steels are made from a hard ceramic material that is designed to gently sharpen and realign the edge of your knife without removing any metal.

The benefits of using a ceramic honing steel are many. For one, it is gentle on your knives, making it ideal for maintaining the sharpness of delicate or expensive blades. Additionally, ceramic honing steels are typically very durable and long-lasting, making them a great investment for any home cook or professional chef.

However, it’s important to note that ceramic honing steels may not be the best choice for all types of sharpening needs. If you have a knife that is extremely dull, you may need to use a different type of sharpener before switching to a ceramic honing steel for maintenance and upkeep.

One potential downside of ceramic honing steels is that they can be brittle and prone to cracking or chipping if dropped or mishandled. To avoid any costly mishaps, be sure to handle them with care and store them properly.

In summary, if you want to maintain the sharpness of your knives while also keeping them in excellent condition, a ceramic honing steel is definitely worth considering. Remember to handle them with care and keep in mind that they may not be the best choice for sharpening very dull knives. And if you’re still not convinced, here are some additional reasons why ceramic honing steels are a great choice:

Diamond Honing Steels

Look no further than diamond honing steels, the secret weapon of professional chefs and home cooks alike. These honing steels are renowned for their durability and effectiveness in sharpening knives.

What sets diamond honing steels apart from traditional ones is their coating of industrial-grade diamonds on the rod. This coating makes them much harder than other honing steels and allows them to quickly and easily sharpen knives. The rough surface created by the diamonds removes metal from the blade, resulting in a sharper edge. Furthermore, diamond honing steels are effective at removing nicks and burrs from the blade, which can help extend the life of your knife.

It’s important to note that diamond honing steels may not be suitable for all types of knives. They work best with harder blades made from materials like stainless steel or high carbon steel. If you have softer blades made from materials such as ceramic or Japanese steel, using a diamond honing steel may cause damage to the blade.

Another thing to consider when using a diamond honing steel is the level of pressure applied. The rough surface of the rod means that using too much pressure when running your knife along it could damage both the blade and the honing steel itself.

In conclusion, diamond honing steels are excellent tools for quick and easy knife sharpening. However, they require careful use and consideration before purchasing to ensure they’re suitable for your knife. If you’re unsure about whether a diamond honing steel is right for you, consult with a professional before making your purchase.

Knife Type and Size Matters

We all know that a good knife is an essential tool in the kitchen. However, did you know that selecting the right type and size of honing steel for your knife is just as crucial as choosing a high-quality knife? Let’s explore why knife type and size matters when it comes to honing.

Firstly, different knives require various types of honing steels. Using the wrong honing steel can cause more harm than good to your knife. For instance, if you own a large chef’s knife, you’ll need a longer honing steel to hone the entire blade correctly. In contrast, a shorter honing steel may be sufficient for a smaller paring knife.

Moreover, the type of steel your knife is made of will also determine which honing steel is best suited for the task. Some honing steels work better with harder steel blades, while others are designed for softer steel blades. Using an incompatible honing steel can cause damage to your knife over time and diminish its lifespan.

Therefore, matching the type and size of your honing steel to your knife is essential. This ensures that you can hone your knife correctly and maintain its sharpness over time. It also makes the honing process quicker and easier.

Benefits of Using the Right Honing Steel

Just like any other tool, having the perfect one for the job makes everything easier and more efficient. But what exactly are the benefits of using the right honing steel?

Firstly, it helps maintain the edge of your knife. Over time, the microscopic teeth on the edge of your knife can become misaligned or bent, causing it to become dull. However, by using a honing steel regularly, you can realign these teeth and keep your knife sharp for longer.

But that’s not all – using the right honing steel can also help prevent damage to your knives. When you use a dull knife, you have to apply more pressure to make cuts, which can increase the risk of slips and accidents. By keeping your knives sharp with a honing steel, you can reduce this risk and protect your investment in quality blades.

It’s important to note that not all honing steels are created equal. Different materials, shapes, and sizes offer different benefits. For example, ceramic honing steels are great for maintaining ceramic knives, while diamond honing steels are ideal for sharpening hard steel knives.

So how do you choose the right honing steel for you? Consider factors like the type of knives you have, how often you use them, and what level of maintenance they require. A traditional steel honing rod is a versatile option that works well for most knives, while more specialized options may be necessary for specific types of blades.

How to Maintain Your Honing Steel

Keeping your honing steel in top shape is essential to maintain the sharpness and longevity of your knives. Here are five sub-sections on how to maintain your honing steel for optimal performance:

Clean your honing steel after every use

After using your honing steel, it’s crucial to clean it thoroughly. Residue or dirt can accumulate on the surface of the steel, affecting its performance. Using a damp cloth or sponge, wipe down the steel and avoid using abrasive cleaners that could scratch the surface.

Store your honing steel in a dry place

Moisture can cause rust to form on the surface of your honing steel. Therefore, it’s important to store it in a dry place after cleaning. Ensure that it’s entirely dry before storing it away; otherwise, it can damage its surface.

Use honing oil or lubricant

Applying a small amount of honing oil or lubricant to the surface of the steel can protect it from rust and ensure that sharpening is smooth. It also helps to reduce friction when drawing your blade.

Avoid dropping or hitting your honing steel

Dropping or hitting your honing steel can cause dents or damage to the surface, affecting its performance. Always handle it with care and store it in a safe place.

Use it correctly

Using your honing steel correctly is crucial to keep your knives sharp and performing at their best. Hold the honing steel vertically on a sturdy surface and place the knife blade at the base of the steel at a 20-degree angle. Draw the blade down the length of the steel while maintaining the angle, repeat on both sides for 10-12 strokes per side.

aT4InZsy50Y” >

Conclusion

To ensure that your knives remain sharp and durable, selecting the appropriate honing steel is critical. With an abundance of options on the market, it’s essential to consider various factors such as material, length, shape, and grit before making a purchase.

When it comes to traditional honing steels, they are ideal for maintaining softer blades. On the other hand, diamond-coated honing steels work best with harder blades. Ceramic honing steels fall somewhere in between and are perfect for maintaining the sharpness of delicate or expensive blades.

Matching the size and type of your honing steel to your knife is crucial to hone your knife correctly and maintain its sharpness over time. Using an inappropriate honing steel can cause damage to your knife over time and reduce its lifespan.

Lastly, keeping your honing steel in top-notch condition is essential to maintain its performance. Clean it after every use, store it in a dry place, use lubricant or oil, avoid dropping or hitting it, and use it correctly.

Investing in a quality honing steel can elevate your cooking game and take your knife skills to the next level.