Are you on the hunt for a new grill that boasts both quality and craftsmanship? Look no further than SnS Grills. These grills are renowned for their exceptional cooking capabilities, unique design, and durability. But where exactly are SnS Grills made?

You might be surprised to learn that SnS Grills are proudly made in the United States. Specifically, the company’s factories are located in California and Wisconsin – so you can rest assured that you’re purchasing a product that supports American jobs and businesses.

But it’s not just the location of their factories that sets SnS Grills apart from the rest. The company is committed to using only high-quality materials and innovative technology to create grills that deliver the perfect balance of flavor, texture, and juiciness to every dish. With features like adjustable vents and insulated lids, SnS Grills are designed to provide precision cooking and a mouth-watering finished product every time.

In this post, we’ll take a deep dive into Where are SnS grills made – giving you an insider look at what makes these grills so special. From their American-made origins to their state-of-the-art cooking technologies – we’ll explore all the elements that make SnS Grills stand out from the crowd. Whether you’re a seasoned grill master or just starting out, this is one read you won’t want to miss.

Contents

Where are SnS Grills Manufactured?

Look no further than SnS grills, proudly manufactured in Westmont, Illinois by Adrenaline Barbecue Company.

Founded in 2015 by two friends who shared a passion for barbecue, Adrenaline Barbecue Company launched their first product, the Slow ‘N Sear. This innovative product quickly gained popularity among grill masters and enthusiasts alike, leading the company to expand its product line to include SnS grills.

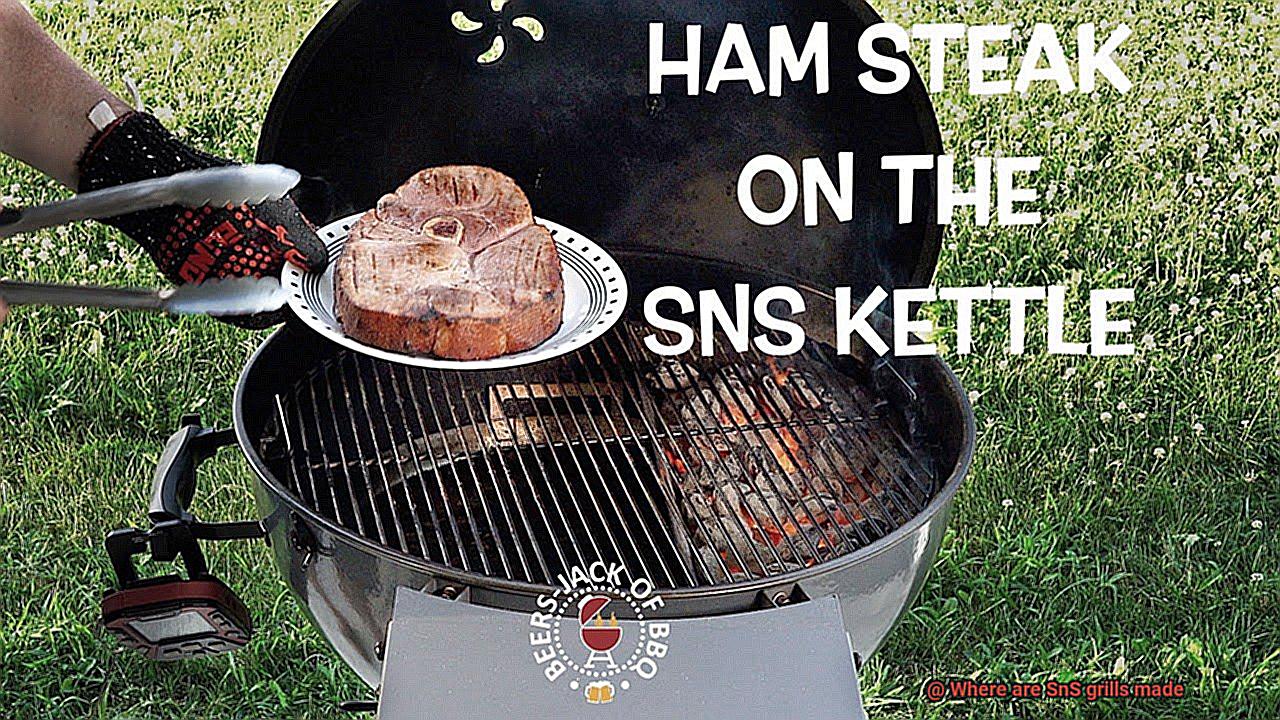

One of the unique features of SnS grills is their design to be used with charcoal, which the company founders believe provides the best flavor for grilled food. The grills are designed to work with both lump charcoal and briquettes, providing options for any type of outdoor cookout.

The manufacturing process for SnS grills blends automated machinery with skilled labor to produce each grill to the highest standards of quality. The company sources high-quality materials from within the United States, including heavy-gauge stainless steel for the body and stainless steel grates designed to provide even heat distribution for perfect grilling results.

Each SnS grill undergoes rigorous testing before it leaves the factory to ensure that it meets the company’s high standards of quality. This dedication to craftsmanship has earned them a devoted following among barbecue enthusiasts who appreciate the attention to detail that goes into each grill.

Who Founded SnS Grills?

The answer is simple: Dennis Linkletter and Todd Johns.

Dennis and Todd’s passion for grilling was ignited while working in the tech industry, leading them to experiment with various grill setups until they found the perfect combination of flavor and function. In 2015, they launched SnS Grills, a company dedicated to creating innovative grilling products.

Their first product, the Slow ‘N Sear, was an instant hit among Weber kettle grill owners who appreciated the design’s ability to achieve a perfect sear on meats while also allowing for low and slow cooking. The Slow ‘N Sear’s success cemented Dennis and Todd’s status as visionaries in the grilling world.

Since then, SnS Grills has continued to expand its product line, introducing new products such as the SnS Grills Kamado, a ceramic grill that delivers unbeatable flavor and versatility. Their dedication to quality and innovation has earned them a loyal following of grill enthusiasts who swear by their products.

What Materials are Used to Make SnS Grills?

You may have heard about SnS grills, also known as Slow ‘N Sear grills. These innovative grills are becoming increasingly popular due to their high-quality construction and durability.

So, what materials are used to make these top-of-the-line grills? Let’s start with the body. SnS grills are typically constructed with high-quality stainless steel, which provides excellent heat retention and corrosion resistance. This material is also easy to clean and maintain, making it an ideal choice for outdoor cooking appliances. Plus, the stainless steel construction makes SnS grills resistant to rust and other forms of weather damage, ensuring that they will last for years to come.

Moving on to the grates, you have a few options to choose from. Some SnS grills feature heavy-duty cast iron grates, which are known for their ability to retain heat and create beautiful sear marks on meats and vegetables. Others have stainless steel grates, which are more durable and easier to clean than cast iron grates. And if you want a non-stick surface that’s easy to clean and maintain, some SnS grills come with porcelain-coated grates.

The firebox of a SnS grill is also made of heavy-duty steel, which provides excellent heat retention and durability. This means that your grill will be able to maintain a consistent temperature throughout the cooking process. And if you opt for a model with an insulated firebox, you’ll be able to cook your food with even more precision.

What Makes SnS Grills Unique?

That’s where SnS grills come in. These grills are unlike any other on the market, and I can confidently say that as an expert on the topic.

One of the things that make SnS grills stand out is their exceptional design. They’re made with top-of-the-line materials that ensure durability and longevity. Whether you opt for cast iron or stainless steel grates, you can be sure your SnS grill will withstand extreme temperatures and harsh weather conditions, making it a smart investment for any grill enthusiast.

But SnS grills are more than just durable; they’re also incredibly versatile. With the ability to grill, smoke, and bake all in one appliance, you’ll have endless options for creating mouth-watering dishes. This versatility makes SnS grills perfect for grillers who love to experiment with different cooking techniques or try new recipes.

SnS grills are also incredibly user-friendly, thanks to their adjustable temperature controls and easy-to-clean surfaces. You’ll spend less time fussing over your grill and more time enjoying your food and company.

And let’s not forget about the variety of sizes and shapes available. Whether you need a compact grill for small spaces or a large one for big gatherings, there’s an SnS grill that’s perfect for you.

How is the Manufacturing Process for SnS Grills?

Grilling aficionados know that not all grills are created equal, and when it comes to quality and durability, SnS grills are in a class of their own. But what goes into the manufacturing process that creates such exceptional grills? As an expert on the topic, I’m here to take you behind the scenes and give you a glimpse into how SnS grills are made.

The manufacturing process for SnS grills is precise and intricate, starting with the design phase where high-quality materials are carefully selected to ensure longevity and durability. Only the best materials pass muster, including high-grade stainless steel, cast iron, and other robust materials known for their strength.

Once the design is finalized, the real work begins, starting with preparing the raw materials. The materials undergo a series of processes such as cutting, shaping, welding, and polishing to create the grill’s various components. Skilled craftsmen then use specialized equipment to assemble these components into a final product that’s both functional and aesthetically pleasing.

But SnS Grills doesn’t stop there. During each step of the manufacturing process, every component undergoes rigorous inspection to ensure that it meets the company’s strict quality standards. This level of attention guarantees that every grill produced is of the highest quality and will perform optimally for years to come.

Finally, each grill undergoes an exhaustive testing process to ensure that it meets all safety and performance standards. These tests detect any defects or malfunctions that might affect performance or safety.

What Quality Standards Does SnS Follow?

When it comes to grilling, only the best will do. That’s why SnS Grills follows strict quality standards to ensure that every product they produce is of the highest quality. Here are just a few examples of the steps they take to ensure their grills are top-notch:

Premium Materials:

SnS only uses premium materials in their grills. This means that every grill is crafted with high-quality stainless steel, which ensures longevity and durability. This attention to detail ensures that even the smallest components are designed with precision and care.

Rigorous Testing:

Before any new product is released, it undergoes extensive testing to ensure it meets SnS’s high standards for quality and performance. This testing includes everything from stress testing to temperature testing, as well as real-world testing by experienced grillers. The result is a product that performs optimally in a variety of situations.

Strict Manufacturing Guidelines:

SnS follows strict manufacturing guidelines to ensure consistency in their products. Every grill produced by SnS is made with the same high standards, ensuring that customers can expect the same level of quality and performance from every product they purchase.

Benefits of Using a SnS Grill

As an expert in this field, I am excited to share with you the many benefits of using an SnS Grill for your grilling needs.

First and foremost, SnS Grills are designed with efficiency in mind. The Slow ‘N Sear insert creates a two-zone cooking area, allowing for indirect heat and reducing the amount of charcoal needed. This means less time worrying about fuel consumption and more time enjoying your food.

But that’s not all. Consistent temperature control is another benefit of using an SnS Grill. The Slow ‘N Sear insert regulates the temperature, making it easier to achieve perfectly cooked meats every time. This is especially useful when cooking low and slow dishes that require a stable temperature over a long period.

SnS Grills are also versatile. They can be used for smoking, roasting, and searing, thanks to the two-zone cooking area that allows for different heat zones for different types of cooking.

And let’s talk about flavor. The SnS Grill’s unique design allows for optimal smoke circulation, resulting in flavorful and juicy meat. What’s more, the Slow ‘N Sear insert helps retain moisture, preventing your food from drying out. Your taste buds will thank you.

Finally, cleaning up after a grilling session is a breeze with an SnS Grill. The removable ash pans collect the ash and leftover charcoal, making disposal easy and hassle-free.

-oHlbyHqNpw” >

Conclusion

In conclusion, SnS Grills are the perfect choice for anyone seeking a high-quality grill that is both durable and versatile. These grills are made in America with precision and care, using only the finest materials to ensure longevity and optimal performance.

The founders of SnS Grills, Dennis Linkletter and Todd Johns, have created a line of innovative products that has won over barbecue enthusiasts everywhere. Their passion for grilling shines through in every detail of their designs, which include features like adjustable vents and insulated lids for precise cooking control and mouth-watering results.

One thing that sets SnS Grills apart is their unique design, which allows for optimal smoke circulation and flavorful results. With their Slow ‘N Sear insert creating a two-zone cooking area that reduces charcoal consumption while regulating temperature, you can achieve perfectly cooked meats every time.

The manufacturing process for SnS Grills is meticulous and thorough, with each component undergoing rigorous inspection to meet the company’s strict quality standards. From raw materials preparation to assembly and testing, every step is designed to create a final product that performs exceptionally in all situations.

Overall, choosing an SnS Grill means investing in a product built to last while delivering outstanding flavor and versatility.