Are you in the market for a new lawn mower? If so, it’s important to consider where it was made and what materials were used. After all, you want a reliable product that will last for years to come. Enter Pro Cut, a brand that has been producing top-notch lawn mowers since 1984.

Pro Cut is well-known in the lawn and garden industry for its durable and efficient mowers. But where are they made? The answer is right here in the USA. Pro Cut takes pride in using high-quality materials and cutting-edge technology to manufacture their mowers. And with exceptional craftsmanship and quality control, you can trust that you’re getting a top-of-the-line product.

In this article, we’ll dive deeper into Pro Cut’s manufacturing process, including the materials they use and their commitment to excellence. Whether you’re a professional landscaper or a homeowner looking for a reliable mower, keep reading to learn more about where Pro Cut mowers are made and why it matters.

Contents

What is Pro Cut?

Pro Cut is a well-known brand in the automotive industry, recognized for their exceptional brake lathes and other related equipment. Founded by Tom and Mary Johnson in 1989, Pro Cut has become a trusted name among automotive professionals and enthusiasts for their high-quality products and exceptional customer service.

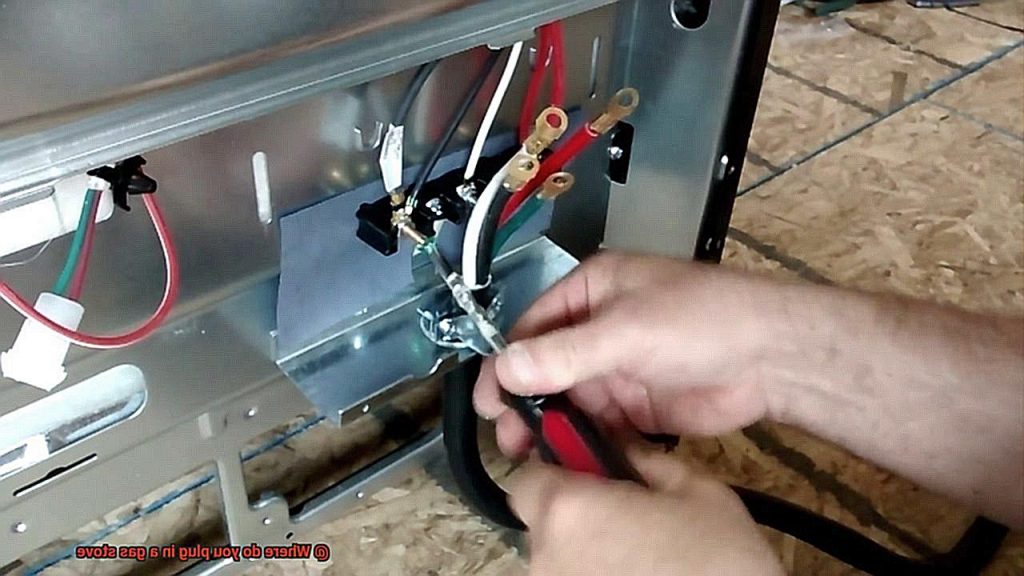

Pro Cut’s flagship product is their brake lathe, designed to resurface brake rotors and drums with speed and precision. The company also offers other brake-related equipment, such as brake caliper presses and brake pad spreaders. Additionally, Pro Cut produces tire machines and wheel balancers that are top-of-the-line in the market.

One of the reasons why Pro Cut has gained such a strong reputation in the industry is due to their commitment to innovation and technology. Their latest brake lathe models come equipped with features such as automatic compensation for runout and vibration, making them even more precise and reliable than previous models. This demonstrates that Pro Cut constantly strives to improve their products with the latest advancements in technology.

Moreover, Pro Cut stands out from other brands due to their dedication to customer support. They offer comprehensive training programs for their equipment, ensuring that users get the most out of their investment. Their technical support team is always available to answer questions or troubleshoot any issues that may arise.

Where is Pro Cut Made?

As a brand that specializes in high-quality meat slicers and food processing equipment, Pro Cut has been in the industry for over three decades. Their base of operations is located in Massachusetts, USA, where their team of experts design and test new products. However, not all Pro Cut products are made in the United States, as many of their products are manufactured overseas in countries such as China and Taiwan.

You might be wondering, how can we be sure that Pro Cut products manufactured overseas meet the same rigorous quality control standards and ethical manufacturing practices as their US-made products? The answer is simple: Pro Cut takes quality control seriously. They ensure that all their overseas facilities meet strict quality control standards and regulations to ensure the same level of quality as their US-made products.

Moreover, Pro Cut works closely with their overseas partners to ensure that they follow ethical manufacturing practices. This shows that the company’s commitment to quality extends beyond just their manufacturing processes.

In addition to their commitment to quality, Pro Cut offers exceptional customer service and technical support for all their products. Whether you’re using a Pro Cut product made in the USA or overseas, you can trust that it was made with care and precision to provide you with exceptional performance.

Why Does Pro Cut Outsource Manufacturing?

One of the main reasons for outsourcing is cost savings. By producing their products in countries with lower labor costs, Pro Cut can save money on manufacturing expenses. This cost savings can then be passed on to customers in the form of lower prices, making their products more accessible to a wider range of consumers.

Another reason for outsourcing is access to specialized skills and expertise. Countries like China, Taiwan, and India have developed expertise in certain manufacturing processes that may not be readily available in the United States. By outsourcing to these countries, Pro Cut can take advantage of their specialized skills and knowledge to produce high-quality products that meet their exacting standards.

Outsourcing also gives Pro Cut the flexibility to scale up or down production as needed without incurring expensive machinery or hiring additional staff. This adaptability allows Pro Cut to respond quickly to changes in demand and stay competitive in a rapidly evolving market.

It’s worth noting that despite outsourcing its manufacturing, Pro Cut maintains rigorous quality control standards. The company carefully selects its overseas partners and closely monitors the manufacturing process to ensure that products meet their exacting specifications. Additionally, all products undergo rigorous testing and quality control inspections before being shipped to customers.

The Quality of Pro Cut Products

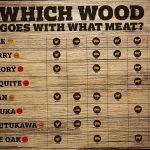

When it comes to grilling, quality tools are a must-have. And if you’re looking for the best of the best, look no further than Pro Cut. This brand is renowned for its commitment to excellence and durability, and their products live up to the hype.

One of the key reasons for Pro Cut’s success is their use of high-grade materials. They only use top-quality stainless steel, which means their products are rust-resistant and can handle high temperatures without warping or cracking. This not only ensures that your grill tools will last for years but also makes them incredibly easy to clean.

But it’s not just about the materials – Pro Cut takes manufacturing to the next level. They use cutting-edge technology to ensure that every product is consistent in terms of size, weight, and shape. This precision is vital for achieving evenly cooked results every time you grill.

What really sets Pro Cut apart, though, is their dedication to rigorous testing. They don’t leave anything to chance – every product undergoes thorough testing for performance, durability, and safety. You can trust that every Pro Cut tool has been put through its paces and is safe to use.

Here are some more reasons why Pro Cut products are the best choice:

- Their products are designed with both form and function in mind, so they look great while also being incredibly practical.

- They offer a range of products to suit all kinds of grilling needs, from tongs and spatulas to skewers and brushes.

- Pro Cut offers a lifetime guarantee on all of their products, which shows just how confident they are in their quality.

Benefits of Outsourcing Manufacturing

The world of business is constantly evolving, and companies are always on the lookout for ways to stay ahead of the game. One strategy that has gained popularity in recent years is outsourcing manufacturing. As an expert in this field, I am excited to share with you the numerous benefits of outsourcing manufacturing.

Cost savings are undoubtedly the most significant advantage of outsourcing manufacturing. By shifting production to a country with lower labor rates, companies can save on labor costs and also benefit from reduced infrastructure and equipment expenses. This translates to increased revenue, which can be channeled into other areas of the business or passed on to customers as lower prices.

Another major advantage of outsourcing manufacturing is increased flexibility. When a company outsources production, it gains the ability to adjust production levels swiftly to meet changes in demand. This means that businesses can respond quickly to market fluctuations without worrying about excess inventory or underproduction.

Outsourcing manufacturing also allows companies to benefit from improved quality control. By partnering with a reputable manufacturer, businesses can rely on their expertise and experience in producing high-quality products. Moreover, most manufacturers have stringent quality control measures in place, ensuring that products meet specific standards.

Finally, outsourcing manufacturing provides access to new markets. Partnering with a manufacturer in a different country opens up new markets and expands the customer base, particularly when entering emerging markets where local knowledge and expertise are crucial for success.

Challenges of Outsourcing Manufacturing

However, this strategy is not without its challenges. As an expert in the field, I have identified several key obstacles that businesses must consider when outsourcing their manufacturing processes.

Firstly, maintaining quality control is a crucial challenge for companies outsourcing manufacturing. In the food industry, this is especially important since safety and quality are paramount. When production is outsourced to a third-party manufacturer, it can be difficult to ensure that the same level of quality is being maintained as when production was done in-house. Companies must establish clear quality standards and monitor the manufacturing process closely to ensure that these standards are met.

Communication is another significant challenge in outsourcing manufacturing. Working with a third-party manufacturer may involve language barriers, time zone differences, and cultural differences that can impede effective communication. This can result in misunderstandings or delays in production. To overcome this challenge, companies must establish clear lines of communication and use technology to facilitate collaboration.

Logistics also pose a challenge when outsourcing manufacturing. Shipping raw materials to the third-party manufacturer and coordinating the shipment of finished products back to the company can add time and cost to the production process. Companies must carefully plan and manage logistics to ensure timely delivery of products.

Finally, outsourcing manufacturing can lead to intellectual property concerns. If a company shares proprietary information or trade secrets with a third-party manufacturer, there is always a risk that this information could be shared or used without permission. Therefore, companies must take measures to protect their intellectual property rights through legal contracts and other means.

Other Companies that Outsource Manufacturing

Outsourcing manufacturing processes has become a popular trend among companies looking to cut costs and streamline their operations. Pro Cut is one such company that outsources their manufacturing, but they are not alone in this practice. In fact, many other prominent companies also outsource their manufacturing to other countries, including Nike and Apple.

Nike, the athletic apparel giant, has been outsourcing their production for years, with the majority of their products being made in countries like China, Vietnam, and Indonesia. Meanwhile, Apple’s products are primarily manufactured in China by companies like Foxconn, despite being headquartered in the United States. This practice has come under scrutiny in recent years due to concerns over working conditions and fair labor practices.

Even companies in industries outside of fashion and technology outsource their manufacturing processes. For example, Black and Decker outsources the production of some of their power tools to companies in China and Taiwan.

While outsourcing can lead to cost savings for companies which can then be passed on to consumers in the form of lower prices, it can also lead to job loss in the United States and raise ethical concerns regarding working conditions and environmental impact. Companies must weigh these factors before deciding whether to outsource or not.

However, outsourcing has its benefits as well. It allows companies to tap into expertise and resources that may not be readily available in-house. Outsourcing can also help companies remain competitive in a global market by allowing them to focus on core competencies while leveraging the expertise of outside suppliers.

ZB6faF8uiTQ” >

Conclusion

When it comes to purchasing a lawn mower, you want to ensure that you’re investing in a high-quality product that will last for years to come. Pro Cut is a brand that has been producing top-notch lawn mowers since 1984, and they take pride in using only the best materials and cutting-edge technology to manufacture their mowers right here in the USA.

What sets Pro Cut apart from other brands is their unwavering commitment to excellence. They maintain rigorous quality control standards throughout every step of the manufacturing process, ensuring that each product meets their exacting specifications. This dedication to quality has earned them a reputation as one of the most trusted names in the lawn and garden industry.

But Pro Cut’s commitment to innovation doesn’t stop at lawn mowers. They’re also well-known in the automotive industry for their exceptional brake lathes and other related equipment. Their use of cutting-edge technology allows them to produce products that are not only durable but also highly efficient and effective.

While Pro Cut does outsource some of its manufacturing processes overseas, they maintain strict quality control measures to ensure that every product meets their high standards. Outsourcing allows them to take advantage of specialized skills and knowledge while also providing cost savings that can be passed on to customers.

Of course, outsourcing isn’t without its challenges. Companies must establish clear quality standards, maintain effective communication, manage logistics carefully, and protect their intellectual property rights. But with Pro Cut’s unwavering dedication to excellence, you can trust that they have taken all necessary precautions to ensure that their products meet the highest standards of quality.

In conclusion, if you’re looking for a reliable mower or automotive equipment, Pro Cut is a brand worth considering.